Power electronics Industries

case studies

1. Alternator Test Bench

It is End of line Test Bench, which measures different parameter of different tests and controlling of Alternator like Load Conditions, Power, Temperature, Harmonics, Vibrations, Noise, over speed of a motor etc. After measuring the data conclude the results of the test based on comparison of read values and expected values and inform to the operator.

There are two types of tests conducted:

1. Routine Test

2. Type Test

Routine Test : After Power On the system will test already written in system.

Type Test: Type test will have a special power to manager to control the types of tests to be conducted by selection of tests.

Key Points :-

1. System will be used to perform routine as well as selection type test as per requirement.

2. System is developed to save test data automatically.

2. Contactor Test Bench

The system is capable of performing a wide-range of tests like, flashing test, pick-up voltage measurement, drop-off voltage measurement, coil current measurement, coil wattage measurement, Drop of Voltage, Pick up voltage test, Humming test, HV test, and many more as per the customer’s requirement. Tests performed in the system:

• Flashing Test

• Coil Current & Coil Wattage test

• Drop off Voltage & Pickup Voltage Test

• Humming Test

• HV Test

Key Points :-

1. All-in-one hybrid bench covering 5 tests.

2. Multi faceted testing and measurement options.

3. Easy to use, easy to read values. Typically suited for R&D engineers.

4. MCB protection.

5. Robust mechanism

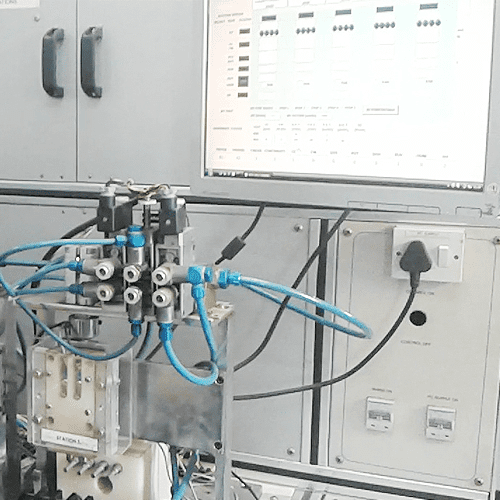

3. Electromagnetic Flow Meter Calibration System

1. This system will be used for calibration of Flow meter and data will be acquired, processed and controlled in LabVIEW.

2. System will have 5 different stations, each station corresponds to different diameter of flow meter.

3. DAQ system consist of NI Hardware cRIO (Real Time Controller).

4. There will be 5 identical Executable systems running on 5 operator stations.

Key Points :-

1. Different types of flow meters can be calibrated on system.

2. Real time display of actual flow.

3. Data accuracy at all stations simultaneously.

related solutions

ATE

EOL

DAQ

LV

Panel Engineering

IIOT

ATE

ATE

Automated Test Equipment (ATE) is a machine designed for performing tests on multiple devices known as devices under test (DUT). An ATE utilizes control systems and automated information technology for performing tests that quantify and calculate a DUT in a timely manner. ATE testing is usually used in Automotive tests, wireless communication and radar as well as electronic component manufacturing. TMCS specialises in integration of offering complete system and sub-systems.

EOL

EOL (End of Line)

End-of-line Tester (EOL) systems can measure and check the functionality of automotive electronic control units, mechanical parts and related systems. Key factors considered are high test quantity, test completion and low system with upgrade costs.

DAQ

DAQ (Data Acquisition System)

National Instruments (NI DAQ) hardware based systems can be used to monitor and record various parameters during vehicle testing, such as engine performance, emissions, temperature, pressure, and vibration. DAQ systems can monitor and record data during these tests, such as load, stress, strain, and temperature measurements, to assess the durability and reliability of the components.

LV

LV (LabVIEW Development Services)

National Instruments is a technology pioneer and market leader in virtual instrumentation, a game-changing concept that has transformed the way engineers and scientists in industry, government, and academia approach measurement and automation.

Panel Engineering

Panel Engineering

Our panel range is available with different specifications in order to meet diverse requirements of the industry like Electrical Panel, control panel, power panel. Panels are designed for convenient layout and reliable wired interconnections between internal and external components.

IIOT