Engineering Service providers

Case studies

1. Compressor Calorimeter test system

While testing the refrigeration performance of a compressor in a laboratory, the equipment which best simulates a real system is a calorimeter. The calorimeter measures capacity by means of a heat balance. The compressor suction pressure is adjusted by controlling the liquid refrigerant, and the temperature of the refrigerant vapour entering the compressor is adjusted by varying the electrical heat input. The discharge pressure is adjusted by varying the temperature and flow of the condensing medium, or by a pressure control device in the discharge line. The system measures parameters like: Suction pressure, Discharge Pressure, Calorimeter Outlet Temperature, Liquid in Temp in Expansion valve, Current, Voltage, Flowrate, Power, etc.

Key Points :-

1. Calibration & Accuracy

2. Graphical & Tabular Format of Data available to Client

3. Analysis of Compressor with Logical and easy operation

2. DAQ for Temperature and Pressure Sensor

1. Data acquisition and monitoring the temperature & pressure

2. Data Monitoring of Crank, Coolant temperature, Engine RPM, Throttle position

Key Points :-

1. User Interactive PC based system

2. Accuracy of data acquired varies while Switching from 0 – 3 Range of Pressure to 0 – 80 Range of pressure.

3. Test report generation

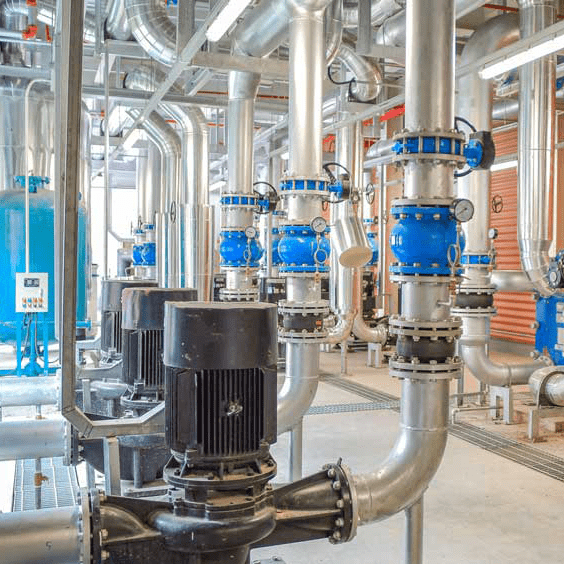

3. Chiller Monitoring System

1. A distributed chiller monitoring system used to monitor and maintain various parameters of a climatic chambers like temperature, pressure, energy, flow of refrigerant to maintain desired temperature.

2. Easy access to data saved for future application and back up.

3. Real time data monitoring, saving and report generation as per user defined format.

4. Selection of remote auto/remote manual mode for fully automatic and semi-automatic control of software over chiller system.

Key Points :-

1. Acquires data from all 5 chillers simultaneously and store it on server computer.

2. Temperature control of 0.2° C.

Turn on/turn off different pumps and compressors from remote computers on single click

related solutions

ATE

EOL

DAQ

LV

Panel Engineering

IIOT

ATE

ATE

Automated Test Equipment (ATE) is a machine designed for performing tests on multiple devices known as devices under test (DUT). An ATE utilizes control systems and automated information technology for performing tests that quantify and calculate a DUT in a timely manner. ATE testing is usually used in Automotive tests, wireless communication and radar as well as electronic component manufacturing. TMCS specialises in integration of offering complete system and sub-systems.

EOL

EOL (End of Line)

End-of-line Tester (EOL) systems can measure and check the functionality of automotive electronic control units, mechanical parts and related systems. Key factors considered are high test quantity, test completion and low system with upgrade costs.

DAQ

DAQ (Data Acquisition System)

National Instruments (NI DAQ) hardware based systems can be used to monitor and record various parameters during vehicle testing, such as engine performance, emissions, temperature, pressure, and vibration. DAQ systems can monitor and record data during these tests, such as load, stress, strain, and temperature measurements, to assess the durability and reliability of the components.

LV

LV (LabVIEW Development Services)

National Instruments is a technology pioneer and market leader in virtual instrumentation, a game-changing concept that has transformed the way engineers and scientists in industry, government, and academia approach measurement and automation.

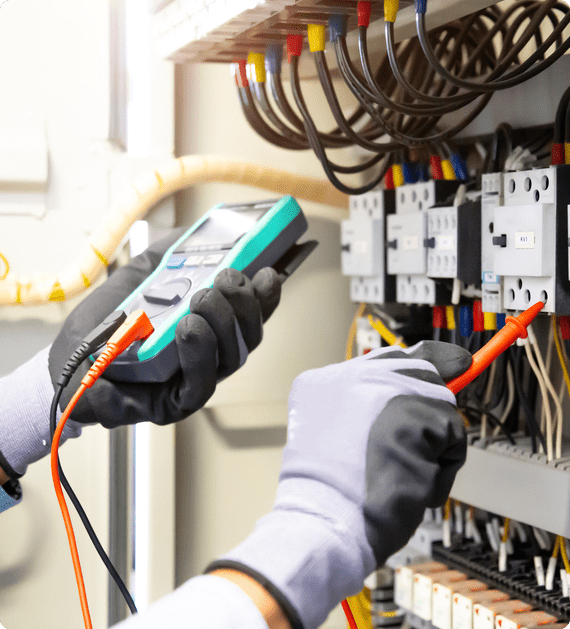

Panel Engineering

Panel Engineering

Our panel range is available with different specifications in order to meet diverse requirements of the industry like Electrical Panel, control panel, power panel. Panels are designed for convenient layout and reliable wired interconnections between internal and external components.

IIOT