We specialize in

Cost Effective Solutions of

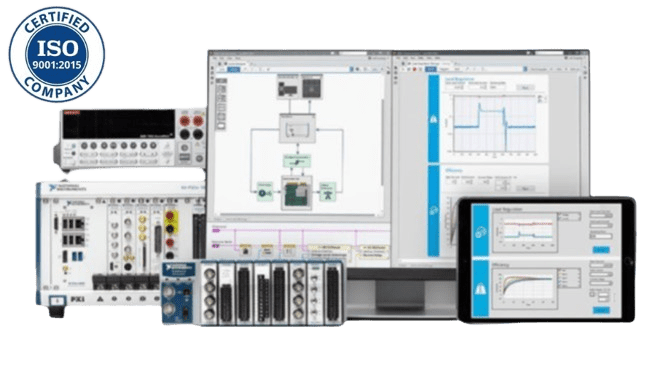

System Integration

Catering to Test, Measurement & Control Solutions

and LabVIEW Software Development

We specialize in

Cost Effective Solutions of

System Integration

Catering to Test, Measurement & Control Solutions

and LabVIEW Software Development

Innovation

in your need

TMCS is a leading service provider of test and measurement solutions for nearly a decade. We cater to a diverse set of industries including Automotive, EV, Aero Defense, Engineering, Oil and Gas, Steel, and Pharmaceutical. Our automotive industry offerings include HIL (hardware in loop), EOL (End of Line), ATEs (Automated Test Equipment), Panel engineering solutions, NI LabVIEW based Data Acquisition systems and software development services. We offer development and V&V (Validation and Verification) to Aerospace & Defense. At TMCS, we believe in competent skills, collaborative approach, effective consultation aided by detailed planning that can fulfil your requirement with no or minimum obstacles.

Advanced solutions for every industry

TMCS Caters to the automotive industry requirements with various tests like Hardware in Loop (HIL) Performance, EOL, Production and Embedded software tests, and Data Logging systems. Vehicle testing and validation….Read More

With customizable off the shelf platforms and systems TMCS serves Aero defense sector with verification and validation systems , Modular Automated Test Equipment for R&D as well as production .Electromechanical set ups, control systems… Read More

Engineering service providers rely on test systems to deliver comprehensive testing and validation to their clients TMCS helps these companies for test fixture design, control panel engineering ,data acquisition and monitoring… Read More

Using hardware platforms such as NI PXI, Compact DAQ we perform testing and validation for Motor drive , inverter etc., Design and Simulation, Power Quality Analysis and pc based data acquisition This includes measuring parameters such as voltage…. Read More

about TMCS

Incepted in the year 2013, We are specialized in developing customized automated test equipment to meet customers’ distinct requirements, which include commissioning industry standard automation, measurement hardware, and software, data acquisition, and control systems. This enables the customer to deliver state of art technological solutions. The Company stands for engineering R&D excellence, dependability, and innovations.

Equipped with extensive experience, the work at TMCS is led by engineers who are nifty with analyzing needs, conceptualizing designs, and building formats that are customized for specific requirements observed across various sectors.

VISION

MISSION

Our Partners

Working in the diversified sectors like automotive , process, Defence, TMCS has joined hands with domain experts with the aim of serving the clients in the best possible way to help them to achieve their goals.

Our solutions

TMCS Caters to the automotive industry requirements with various tests like, Hardware in Loop (HIL) Performance, EOL, Production and Embedded software tests, Data Logging systems. Vehicle testing and validation systems for , Endurance, Durability, performance checking Automotive segment is classified based on the applications served e.g., Body and Chassis, Active Safety, Powertrain, infotainment.

ATE (Automated Test Equipments)

EOL

DAQ

LV

Panel Engineering

IIOT

ATE (Automated Test Equipments)

ATE

Automated Test Equipment (ATE) is a machine designed for performing tests on multiple devices known as devices under test (DUT). An ATE utilizes control systems and automated information technology for performing tests that quantify and calculate a DUT in a timely manner. ATE testing is usually used in Automotive tests, wireless communication and radar as well as electronic component manufacturing. TMCS specialises in integration of offering complete system and sub-systems.

EOL

EOL (End of Line)

End-of-line Tester (EOL) systems can measure and check the functionality of automotive electronic control units, mechanical parts and related systems. Key factors considered are high test quantity, test completion and low system with upgrade costs.

DAQ

DAQ (Data Acquisition System)

National Instruments (NI DAQ) hardware based systems can be used to monitor and record various parameters during vehicle testing, such as engine performance, emissions, temperature, pressure, and vibration. DAQ systems can monitor and record data during these tests, such as load, stress, strain, and temperature measurements, to assess the durability and reliability of the components.

LV

LV (LabVIEW Development Services)

National Instruments is a technology pioneer and market leader in virtual instrumentation, a game-changing concept that has transformed the way engineers and scientists in industry, government, and academia approach measurement and automation.

Panel Engineering

Panel Engineering

Our panel range is available with different specifications in order to meet diverse requirements of the industry like Electrical Panel, control panel, power panel. Panels are designed for convenient layout and reliable wired interconnections between internal and external components.

IIOT

IIOT

client testimonials

We have been using TMCS System for few months now. Team have been consistent in Quality and have maintained delivery schedules. They have been very flexible working in cross continent timing and logistic issues. Thank you team.

- Fortune 500 Company

Thank you team, for the commitment and competency you have delivered. Your prompt support helped us during execution,

- Manager- ME- Automotive Conglomerate

TMCS has worked for one of our critical Test bench project. The technical team was well versed with the project documents. We are delighted to experience their prompt responses and thorough work on the testbench during online and onsite support . They delivered the project to the expectations in professional manner.

- Engineering Manager

Using LabVIEW and the LabVIEW RIO Architecture allowed us to quickly prototype our Shox and validate them on field before presenting them to client. The ease of use of the NI platform helped us reduce the development and validation time of our design by 30%

- Manager Control System